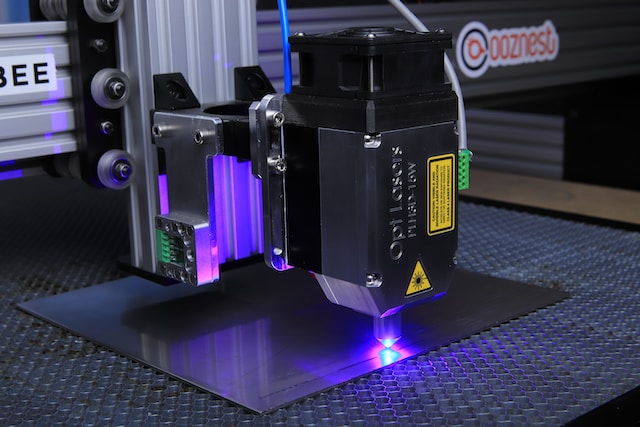

Are you prepared to see for yourself the incredible strength and accuracy of metal laser cutters? Prepare yourself for an exciting adventure into the realm of these amazing devices that is about to begin. Metal laser cutters have changed the game in many industries, from producing complex patterns to transforming industrial manufacturing processes.

Knowing the ins and outs of metal laser cutters is crucial, regardless of whether you’re a hobbyist searching for a cutting-edge instrument or a business owner hoping to improve efficiency and quality. We’ll go into great detail about their varieties, benefits, and offer helpful advice for selecting the best one in our extensive guide.

It’s time to let the sparks fly, so buckle up and get ready to unleash the full potential of metal laser cutters!

Metal Laser Cutters Types

There are several different kinds of metal laser cutter on the market. Every variety satisfies distinct demands and specifications while possessing special qualities and benefits of its own. Let’s examine a few of the most prevalent kinds:

- CO2 Laser Cutters: These devices cut through metal with a carbon dioxide laser beam. They are adaptable and have the ability to work with a variety of materials, such as titanium, aluminium, and stainless steel.

- Fibre Laser Cutters: As the name implies, these devices create a powerful laser beam by using fibre optic technology. When it comes to cutting thin metals like copper or brass, they are renowned for their extraordinary speed and precision.

- YAG Laser Cutters: Yttrium-Aluminum-Garnet (YAG) lasers can be used to cut thin sheets of metal, such as silver or gold, in addition to being frequently used for marking or engraving on metal surfaces.

- Hybrid Laser Cutters: These devices combine fibre and CO2 lasers to offer versatility in effectively cutting a range of materials.

- CNC Plasma Cutter with Laser Module: This kind offers a potent answer for heavy-duty metal fabrication applications by fusing laser cutting capabilities with plasma arc technology.

When choosing the best kind of metal laser cutter for your requirements, it’s critical to take into account elements like material thickness, required precision levels, production volume, maintenance expenses, and budget.

The Benefits of Metal Laser Cutting

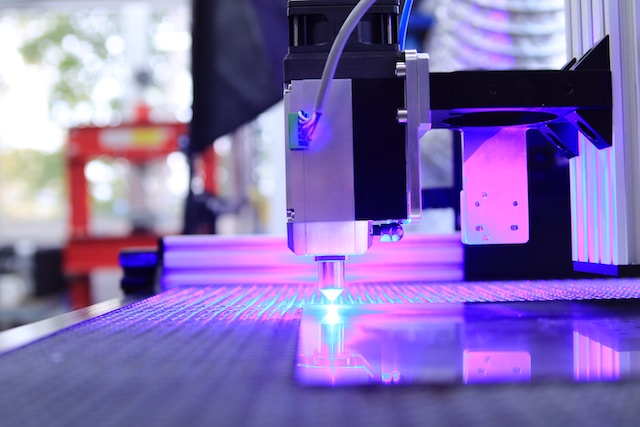

- Precision and Accuracy: The capacity of a metal laser cutter to produce precise and accurate cuts is one of its greatest benefits. Precise control over the laser beam makes it possible to create complex designs with close tolerances. It’s crucial to maintain this degree of precision while working with intricate shapes or tiny parts.

- Versatility: Steel, aluminium, brass, and copper are just a few of the metals that metal laser cutters can cut through, depending on their type and thickness. If necessary, they can even work with other materials like plastic or wood. Their adaptability renders them appropriate for an extensive array of uses in various sectors.

- Speed and Efficiency: When compared to conventional cutting techniques, metal laser cutters are renowned for their speed and efficiency. Instead of cutting through the material over hours, the laser beam slices through it in a matter of seconds or minutes. This improves productivity in manufacturing processes while also saving time.

- Clean Cuts: You can anticipate burr- and rough edge-free cuts when utilising a metal laser cutter. The substance is smoothly melted away by the concentrated laser beam, leaving the surrounding environment undamaged. This removes the requirement for extra processing steps or finishing touches.

- Minimum Waste: The narrow kerf width—the width of material eliminated during cutting—of metal laser cutting results in minimum waste. Businesses can reduce their raw material prices and improve their environmental impact by minimising material waste.

- Flexibility in Design: The options for design are tremendously expanded by metal laser cutting. A metal laser cutter allows you to easily make extremely detailed designs, regardless of the complexity of the pattern or the simple forms you need to cut.

- Cost-effective Solution: Because of their high levels of precision and efficiency, metal laser cutters turn out to be a cost-effective solution over time, even though they may demand an upfront investment. Through the reduction of production time and the mitigation of errors resulting from manual cutting procedures, companies can gradually enhance their overall profitability.

Advice on Selecting the Best Metal Laser Cutter

Selecting the ideal metal laser cutter can significantly impact your cutting processes. Here are some crucial pointers to think about before choosing:

- Determine your exact needs: It’s important to determine your exact needs before making an investment in a metal laser cutter. Think about things like the kind and thickness of the materials you plan to deal with, the volume of output you want to achieve, the cutting speed you want, and your budget.

- Investigate other brands and models: Invest some time in learning about the numerous producers and models that are on the market. Search for respectable companies that are well-known for their dependability and fine craftsmanship.

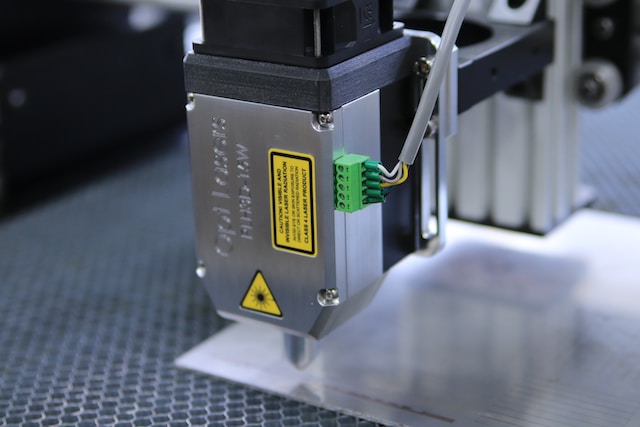

- Take power output into consideration: A metal laser cutter’s power output dictates how well it can cut. Though they can cost more, machines with higher wattages can handle thicker materials more effectively.

- Search for qualities that offer precision: In applications involving metal cutting, precision is essential. To guarantee accurate cuts each and every time, look for features like autofocus systems, excellent positioning precision, cutting-edge motion control technology, and sophisticated sensing capabilities.

- Verify software compatibility: If you want an all-in-one solution, be sure the laser cutter you select can be utilised with widely used design software or has an easy-to-use software interface of its own.